We have special single-purpose machines and are able to deliver your product faster and more efficiently.

Thanks to our variety of production equipment, we are able to deliver products in large quantities.

We are accustomed to delivering all orders on time.

It all starts with the input material. We are able to transform different types of tubes, sheets, profiles or square and multi-angled bars into the final product. To do this, we use custom-built production equipment that functions precisely and very quickly and can handle high loads.

Our workshop is extensively equipped. It includes, among others, eccentric and hydraulic pressing machines, NC bending presses, CNC machining centre, milling machines, lathes, cam machines, sheet-metal shears, metal saws, MIG/MAG and TIG welders, hardening furnace and other specialised equipment.

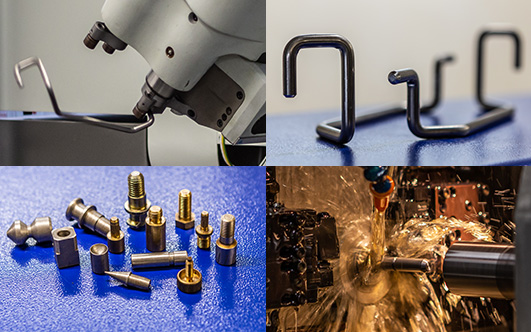

We have provided wire bending since 2012. Our newest machine allows 3D wire bending, with the diameter of 3 to 10 mm, depending on the strength of the wire. The high accuracy and repeatability of the bends is achieved by a state-of-the-art computer control system. The large production capacity predisposes the machine to seamlessly produce series/batches of thousands. However, thanks to the rapid adjustment, we can also produce small batches of hundreds of pieces.

We deal with turning small parts on cam-type automatic machines and CNC long-running lathes. Our products achieve high precision according to customer requirements. The advantages of the large production capacity are most evident in batches of thousands of pieces. We turn parts up to the diameter of 40 mm.

DELTA METAL s.r.o.

Nová 1195, 696 01 Rohatec

IČ: 25348892

DIČ: CZ25348892

+420 608 918 240

info@deltametal.cz

The company is registered by the Regional Court in Brno, section C, insert 27761.

Do you have any questions?

Would you like a quotation?

Write a short message to us.